Tour:

A Pictorial Chronology of the Rebuilding of a Model "A" Ford Engine

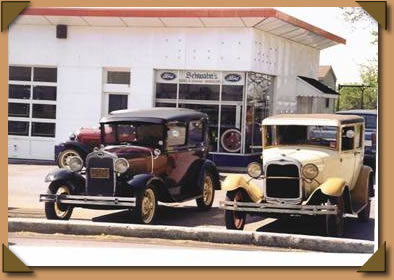

"Welcome

to our new shop!"

Step

#1

Step

#1

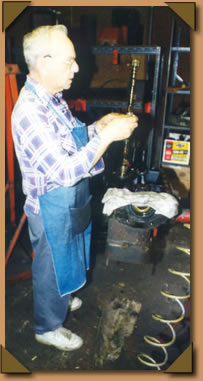

Engines are disassembled

in the "dirty room" and each part is checked with a micrometer for acceptable

tolerances by Harry (who owns a '29 "A" Sport Coupe). Ora's father,

Ira, also assists.

Step

#2

Step

#2

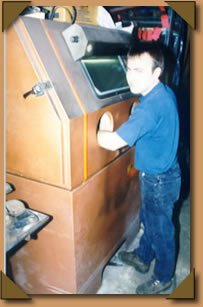

Continuing with

the disassembly process, the engine block is Magnafluxed, a process

that searches for engine block cracks from freezing or metal fatigue.

Step

#3

Step

#3

All parts are thoroughly

cleaned (not shown), then bead blasted to remove remaining paint and

dirt, and immediately labeled to ensure that a customer's parts stay

with the proper engine block.

Step

#4

Step

#4

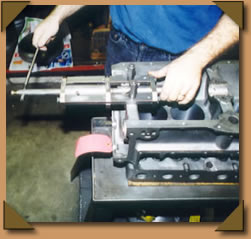

The engine block

is next brought to the shop for "deck resurfacing" (the surface where

the head attaches to the engine block is milled perfectly flat). The

cylinder head and manifold assembly are also done in the same manner

(not shown).

Step

#5

Step

#5

The cylinders are machined by a boring bar to the next oversize diameter piston size available. If the maximum bore (diameter) has been reached, the cylinders are sleeved, returning the bore to the original (standard) diameter.

Step

#6

Step

#6

The valve seats

of the deck surface are bored to install hardened valve seats.

Step

#7

Step

#7

As shown by Ora,

the new valve seats are installed and ground with three angled surfaces

- 60,45, and 30 degrees.

Step

#8

Step

#8

The engine block

is inverted. A "fixturing mold" is placed on each half of a bearing

surface and molten Babbitt is poured in the mold, creating a new bearing

surface.

Step

#9

Step

#9

Oil grooves are

cut in the new Babbitt (bearing surface) with a special cutter.

Step

#10

Step

#10

A few of the engine

blocks and cam shafts under re-manufacturing - note the red identification

tags on all parts.

Step

#11

Step

#11

The roughly poured

main bearings are line bored to accept the machined surface of the crankshaft

- each half of the main bearing cap is laid aside in the picture to

allow a full view of the boring bar.

Step

#12

Step

#12

An optional process for standard crankshafts, the crankshaft, flywheel and pressure plate are spun dynamically to measure their balance coordinates. Imbalances are removed. (Note: this process is mandatory for counterweighted crankshafts. See step #13.)

Step

#13

Step

#13

Counter weights are added to the crankshaft. Theoretically, it prolongs the engine life, and the engine runs smoother. Typically, this is done in conjunction with the lightening of the flywheel and the use of a modern V8 pressure plate.

Step

#14

Step

#14

The cylinder walls

are honed to size to accept the new pistons and rings; and the block

receives a final cleaning (not shown). The engines are placed on bench-mounted

stands for final assembly - all parts have been painted as required,

for each engine, by Jan when this stage is reached.

***********************************************

Additional processes normally performed on an engine, but not shown,

include crankshaft journals regrinding, connecting rods reconditioning,

cam lobes regrinding, flywheel and pressure plate balancing (see pictures

#12 and #13 for the balancing of crankshafts), balancing of pistons

and connecting rods, and reconditioning and balancing of flywheel and

pressure plate.

Step

#15

Step

#15

This is an example of a completed engine and transmission that has gone through the 2 to 3 month rebuilding process.

Fini!!!